- Home

- Business Processes

- Industry Knowledge

- Aerospace Industry

- Automotive Industry

- Banking Domain

- BFSI Industry

- Consumer/ FMCG Industry

- Chemicals Industry

- Engineering & Construction

- Energy Industry

- Education Domain

- Finance Domain

- Hospitality Domain

- Healthcare Industry

- Insurance Domain

- Retail Industry

- Travel and Tourism Domain

- Telecom Industry

- Leadership Skills

- eLearning

- Home

- Business Processes

- Procure to Pay

- Define Accounts Payable

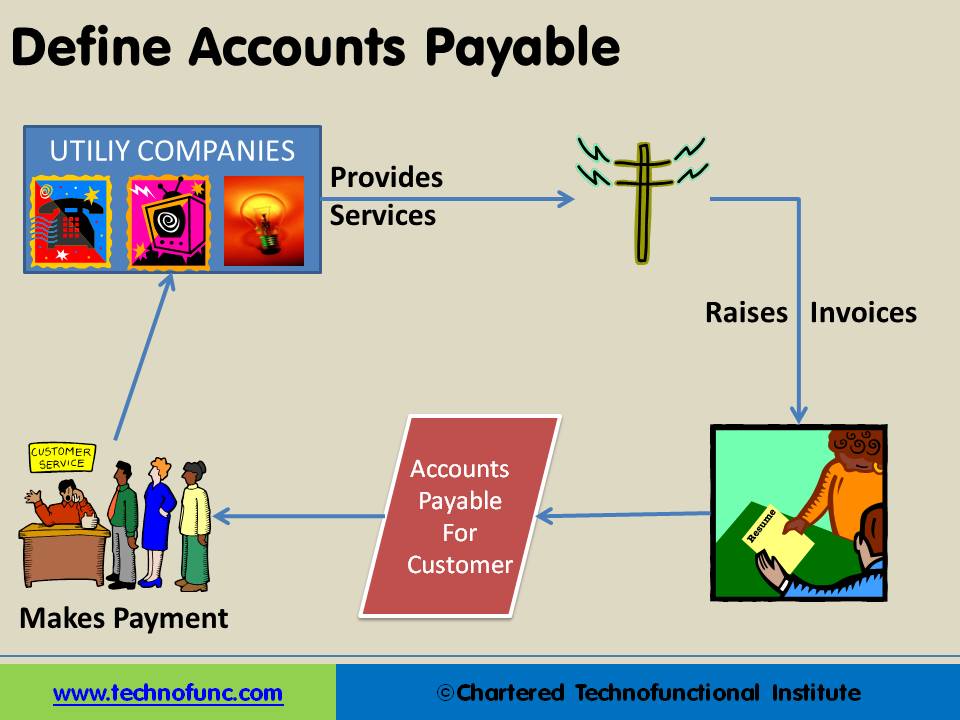

Define Accounts Payable

Payables are often categorized as “Trade Payables” & “Expense Payables”. “Trade Payables” are the monies due for the purchase of physical goods that are recorded in Inventory. “Expense Payables” are the monies due for the purchase of goods or services that are expensed.

How do we define Accounts Payables:

We all use utilities. For example we take various services from the phone company, the gas company and the cable company. They provide us the goods and services first and as the end of the agreed billing period they raise an invoice on the customer. In this case the Utility Company is our Creditor and they have provided us the service on credit. The amount payable to the utility company is the “Account Payable” for us, which needs to be paid in very short-term to the utility company (Supplier/Creditor) to enjoy continued services.

Similarly credit is extended in the normal course of business to the customers on purchase of goods and services and needs to be paid off within a given period of time in order to avoid default.

Payables are often categorized as “Trade Payables” & “Expense Payables”. “Trade Payables” are the monies due for the purchase of physical goods that are recorded in Inventory. “Expense Payables” are the monies due for the purchase of goods or services that are expensed. Common examples of Expense Payables are utilities like telephone and electricity.

Related Links

You May Also Like

-

Payables are often categorized as “Trade Payables” & “Expense Payables”. “Trade Payables” are the monies due for the purchase of physical goods that are recorded in Inventory. “Expense Payables” are the monies due for the purchase of goods or services that are expensed.

-

Subsidiary Ledgers – AP Ledger

An accounts payable invoice gets recorded in the Account Payable sub-ledger at the time an invoice is received and validated that the respective goods corresponding to the invoice have been received. Then it is verified and vouchered for payment as per the payment terms agreed with the Supplier.

-

When a customer wants a product that has been stored in the warehouse, the same need to be picked off the shelf (or off the floor) and get it ready for shipping. Depending on how big is the warehouse, picking can take a while. (Many distribution centers cover more than 1 million square feet.). Hence, warehouse order picking methods are an important aspect within any warehouse.

-

At a high level, the essential elements in a warehouse are an arrival bay, a storage area, a departure bay, a material handling system and an information management system. As part of the process for enabling a warehouse layout, you must define warehouse zone groups, and zones, location types, and locations.

-

After products have been received and passed a quality inspection, they need to be stored so that you can find them when you need them. This process is called putaway. The spot where you store a particular product is called a location. One section of a warehouse might have small locations for light items; another area may have large locations on the floor for heavy items.

-

Understand what we mean by accounts payable. Why the process is called accounts payable and what are the other names by which this process is known as. Download a ready recokner to keep with you.

-

One of the most important decisions when running a warehouse is its layout. Warehouse layout defines the physical arrangement of storage racks, loading and unloading areas, equipment and other facility areas in the warehouse. A good layout aligned with the business needs could have a significant effect on the efficiency.

-

Warehouses may seem like a simple, straightforward concept, but they actually include a variety of different types of warehouses that all have their own niche. The type of warehousing that’s right for you depends on your specific industry, location, and needs. From private warehousing, distribution centers, and climate-controlled warehouses, there’s an option to suit every business.

-

Overview of Warehouse Processes

The basic function of a warehouse is to store goods. This means that they receive deliveries from suppliers, do any necessary checking and sorting, store the materials until it is dispatched to customers. Traditionally warehouses were seen as places for the long-term storage of goods. Now organizations want to optimize their customer experience and try to move materials quickly through the supply chain, so the role of warehousing has changed.

-

Understand the Accounts Payable process. Understand the AP cycle and the various tasks that need to be completed during AP transaction processing. Learn the key activities and setups that are done in any typical system during the AP processing.

Explore Our Free Training Articles or

Sign Up to Start With Our eLearning Courses

About Us

Learning

© 2023 TechnoFunc, All Rights Reserved